Glass is one of the most popular and versatile building materials used today because of its constantly improving solar and thermal performance. One way this performance is achieved is through the use of passive and solar control Low-E coatings. Low-E or low emissivity (low thermal emissivity) refers to a surface condition that emits (gives off) low levels of radiant thermal (heat) energy. All materials absorb, reflect and emit radiant energy. Emissivity is the value (on a scale between 0 and 1) given to materials based on the ratio of heat emitted in comparison to a blackbody. A blackbody would have an emissivity rating of 1 and a perfect reflector would have a value of 0. Reflectivity is the opposite of emissivity and when they are added together their total should be equal to 1.

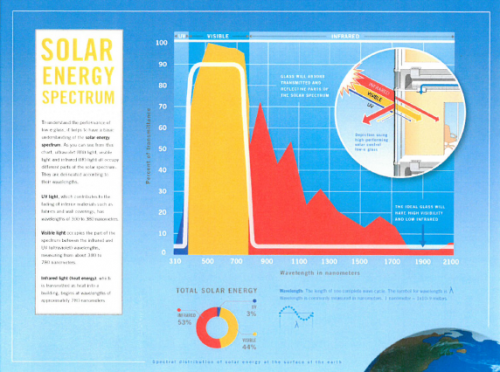

In order to understand Low-E coatings, it is important to understand the solar energy (energy from the sun) spectrum. Ultraviolet (UV) light, visible light and infrared (IR) light all occupy different parts of the solar spectrum – the difference between the three are determined by their wavelengths.

- Ultraviolet light, which is what causes interior materials such as fabrics to fade has wavelengths of 310 – 380 nanometers when measuring glass performance (a nanometer being one billionth of a meter).

- Visible light occupies the part of the spectrum between wavelengths of about 380 – 780 nanometers.

- Infrared light (heat energy) is transmitted as heat into a building and begins at wavelengths of 780 nanometers. Solar infrared is commonly referred to as short-wave infrared energy while heat radiating off of warm objects has higher wavelengths than the sun and is referred to as long-wave infrared.

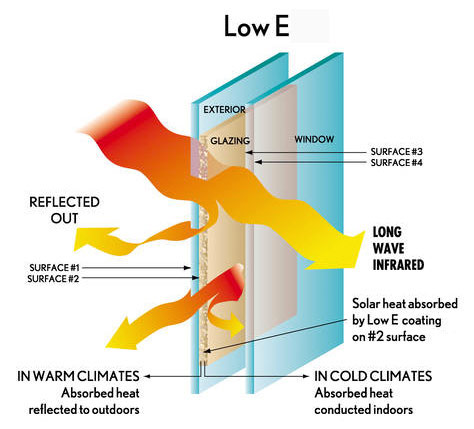

Low-E coatings have been developed to minimize the amount of ultraviolet light that can pass through glass without compromising the amount of visible light that is transmitted. When heat or light energy is absorbed by glass, it is either shifted away by moving air or radiated away by the glass surface. This is emissivity. Reducing the emissivity of one or more of the window glass surfaces improves a window’s insulating properties. Uncoated glass has an emissivity of 0.84 while some low-E coated glass can have as little as a 0.02 rating. Low-e glass has a microscopically thin transparent

coating, a coating much thinner than a human hair, that reflects heat (long-wave infrared energy).

Some low-E glass also reflects significant amounts of short-wave solar infrared energy. During winter when the interior energy tries to escape to the colder outside, the low-E coating reflects the heat back

to the inside, reducing the radiant heat loss through the glass. During the summer the reverse happens. To use an analogy, Low-E glass works the same way as a thermos does. A thermos has a silver lining which reflects the temperature of a drink it contains back into the drink. The temperature is maintained because of the constant reflection that occurs as well as the insulating benefits that the airspace (which is between the inner and outer shells of the thermos) provides, similar to an insulating glass (IG) unit. Since Low-E glass is comprised of extremely thin layers of silver or other low emissivity materials, the same theory applies. The silver Low-E coating reflects the interior temperatures back inside keeping the

room either warm or cool.

There are two different types of Low-E coatings: passive coatings and solar control coatings. Most passive Low-E coatings are fused to the glass (known as the pyrolytic process) when the glass is being manufactured. Passive Low-E coatings are good for very cold climates because they allow some of the sun’s short-wave infrared energy to pass through and help heat the home or building during

the winter while continuing to reflect interior long-wave heat energy back inside. Most solar control Low-E coatings (MSVD process) have the coating applied to pre-cut glass in a vacuum chamber at room

temperature. This coating is softer than the passive low-E process and needs to be sealed in an IG unit and has lower emissivity but superior solar control performance which is ideal for mild to hot climates dominated by air conditioning use.

In a standard double panel IG unit there are four surfaces that the Low-E coating can be applied to; 1. the surface facing outdoors, 2. surfaces facing each other inside the insulating glass unit separated by airspace and an insulating spacer and 3. the surface facing indoors.

The following are used to measure the effectiveness of Low-E coatings:

- U-Value is the rating given to a window based on how much heat loss it allows.

- Visible Light Transmittance is a measure of how much light passes through a window.

- Solar Heat Gain Coefficient is the fraction of incident solar radiation admitted through a window, both directly transmitted and that is absorbed and reradiated inward. The lower the window’s solar heat gain coefficient (SHGC) the less solar heat it transmits.

- Light to Solar Gain is the ratio between the window’s solar heat gain coefficient and its visible light transmittance (VLT) rating.

How can homeowners tell if their windows have Low-E glass? The Low-E coating is usually placed on one of the inside glass pane surfaces of the insulating unit. Homeowners can test for a Low-E coating in a window by doing the following:

- Hold a match or pen light up in front of the window. In a double pane insulating glass unit, four reflections or light (or two per lite of glass present) will appear due to the four glass surfaces of the insulating glass unit.

- If the window contains Low-E glass one of the images will be a different color than the rest of the images.

- If the window does not have Low-E glass the four reflected images will be the same color.

ENERGY STAR is a US Environmental Protection Agency (EPA) voluntary program that helps businesses and individuals save money and protect our climate through superior energy efficiency. ENERGY STAR requires that the energy performance of all windows, doors and skylights must be independently tested and certified according to test procedures established by the NFRC, the National Fenestration Rating Council. The NFRC is a third-party non-profit organization that sponsors certified rating and labeling to help consumers compare the performance of windows, doors and skylights. The NFRC does not distinguish between good and bad windows but ENERGY STAR does and it enables consumers to easily identify NFRC certified products with superior energy performance. A link to the ENERGY STAR window and door performance ratings can be found here: https://www.energystar.gov.